OUR SERVICES

- Home

- Our Services

Our Services

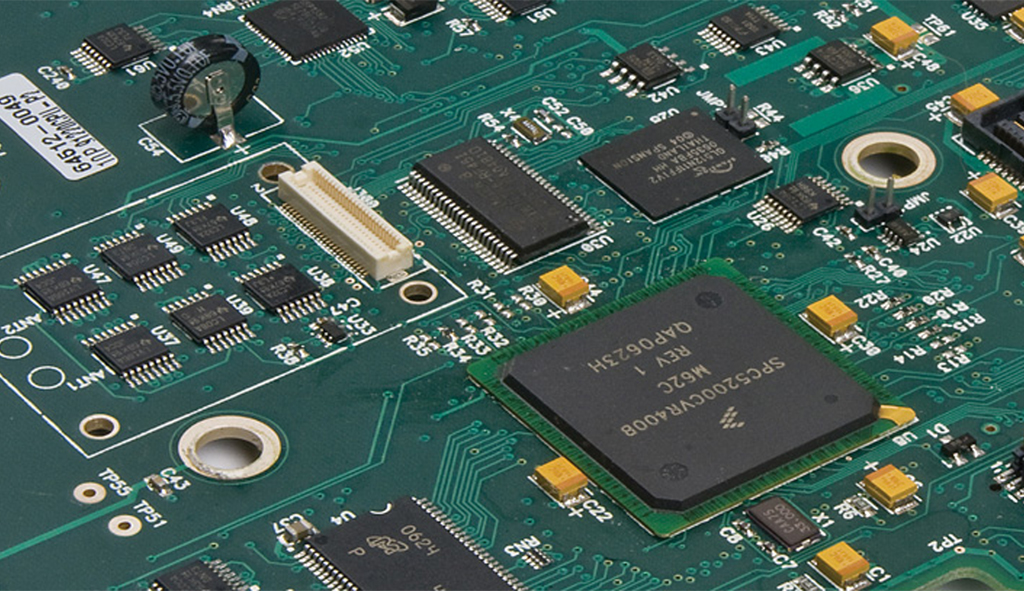

EMBEDDED HARDWARE

- Schematic Design

- Schematic Capture

- Circuit Board Layout

- Circuit Board Prototyping

- Board Bring Up

EMBEDDED FIRMWARE

- Driver Design & Implementation

- User Interface Design & Implementation

- Test Software

- Full Application Design & Implementation

- PC Software Utility Design & Implementation

TEST SERVICES

- Test Plan Design

- Automated Testing

- Product Validation

- Production Test Design

- Temperature Testing

Product Development Process

1. TEST PLAN DESIGN

Our experienced test developer will put together a plan to ensure the final product will meet the requirements that were laid out during the engagement. This will allow us to clearly define what success looks like before starting the design. If at any time during the project the scope is changed, the test plan will be updated before any design work is completed.

2. HIGH LEVEL DESIGN

A high level design document will be built to translate the requirements into an architecture and specific implementation pieces. This will be used as a guide for everyone involved in the project.

3. DETAILED DESIGN

The detailed design can take many forms. For hardware it might be a schematic, board layout, and Bill Of Materials (BOM). For software, it would be code, build scripts, and interface descriptions. For mechanical it would be detailed drawings and 3D models. Whatever is required for your product, we have the people with the right skill set.

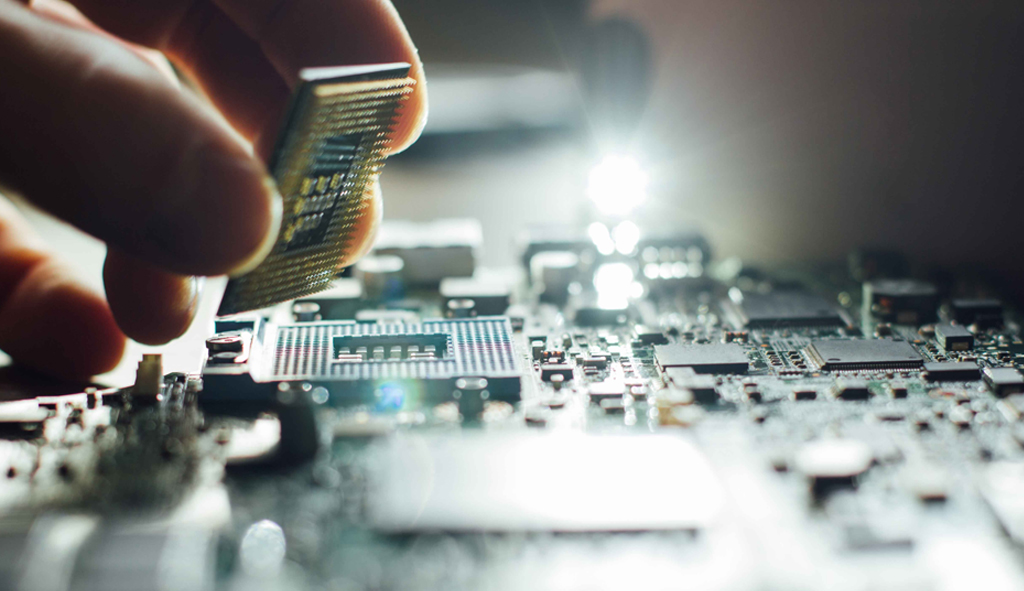

4. ALPHA PROTOTYPE

The detailed design will be used to build an alpha prototype. This will be a physical circuit board that is populated with components and loaded with basic driver level software. The goal of the alpha stage is to prove out the design. It will help to discover and correct any issues early on. A first version of the mechanical design is fabricated at this stage to ensure the proper form and function.

5. FUNCTIONAL TEST

Test software as well as other circuit boards to support testing will be developed at this time. The goal of this stage is to fully test the design. Depending on the scope of the project, this may involve automated testing. Any issues that are discovered are corrected both on the physical prototype and in the design.

6. BETA PROTOTYPE

A second prototype is created to implement all of the changes made during functional test. This prototype will once again be tested to ensure that the design functions correctly. If any other issues are found, another cycle of testing and prototyping will be undertaken.

7. PRODUCTIZATION

The final electronics will be assembled with mechanicals at this stage. Any labels, packaging, instructions, or other materials as required will be designed. The final package and high level bill of materials will be put together.

8. CERTIFICATION

If any certifications are required, the design and samples will be submitted for testing. During this phase, we will work with the certifier to answer questions, provide additional materials, and make changes if required. If you prefer to deal with the certifier directly, we can pass off the required materials at this point and provide support as needed.

9.PRODUCT VERIFICATION

Product verification is the final testing stage for the completed product before field trial. It is used to validate the design versus the requirements and ensure that the product meets the customer’s needs fully. During this phase, the tests will be implemented such that they can be used during mass production of the product.

10. FIELD TRIAL

A field trial allows for exposure to end customers and gathering of data in real world scenarios. This will allow for any feedback that can be used to further improve the product before mass production. We can provide whatever support is required during this phase of testing with your customers.

11. FULL PRODUCTION

We are capable of working with our contract manufacturer or another of your choosing to introduce the design, create assembly drawings and instructions, setup test procedures, and validate first articles. Once full production is underway, we can continue to engage the factory to address quality issues or increase efficiency and yield.

12. MAINTENANCE

Any long term product requires ongoing maintenance. This might be the resolution of software defects, addition of software features, modifications to the hardware, component obsolescence, or changes to documentation. We are happy to continue to work with you over the life of your product.